Modern industry is constantly looking for ways to optimize operations, improve worker safety and increase efficiency. In this context, the use of remotely controlled robots offers exceptional advantages. These versatile machines, remotely controlled by human operators, have become valuable allies in many industries. In this article, we will explore the multiple benefits of using remotely controlled robots in the industrial environment, highlighting their ability to improve safety, operational efficiency and overall productivity.

Increased safety for workers

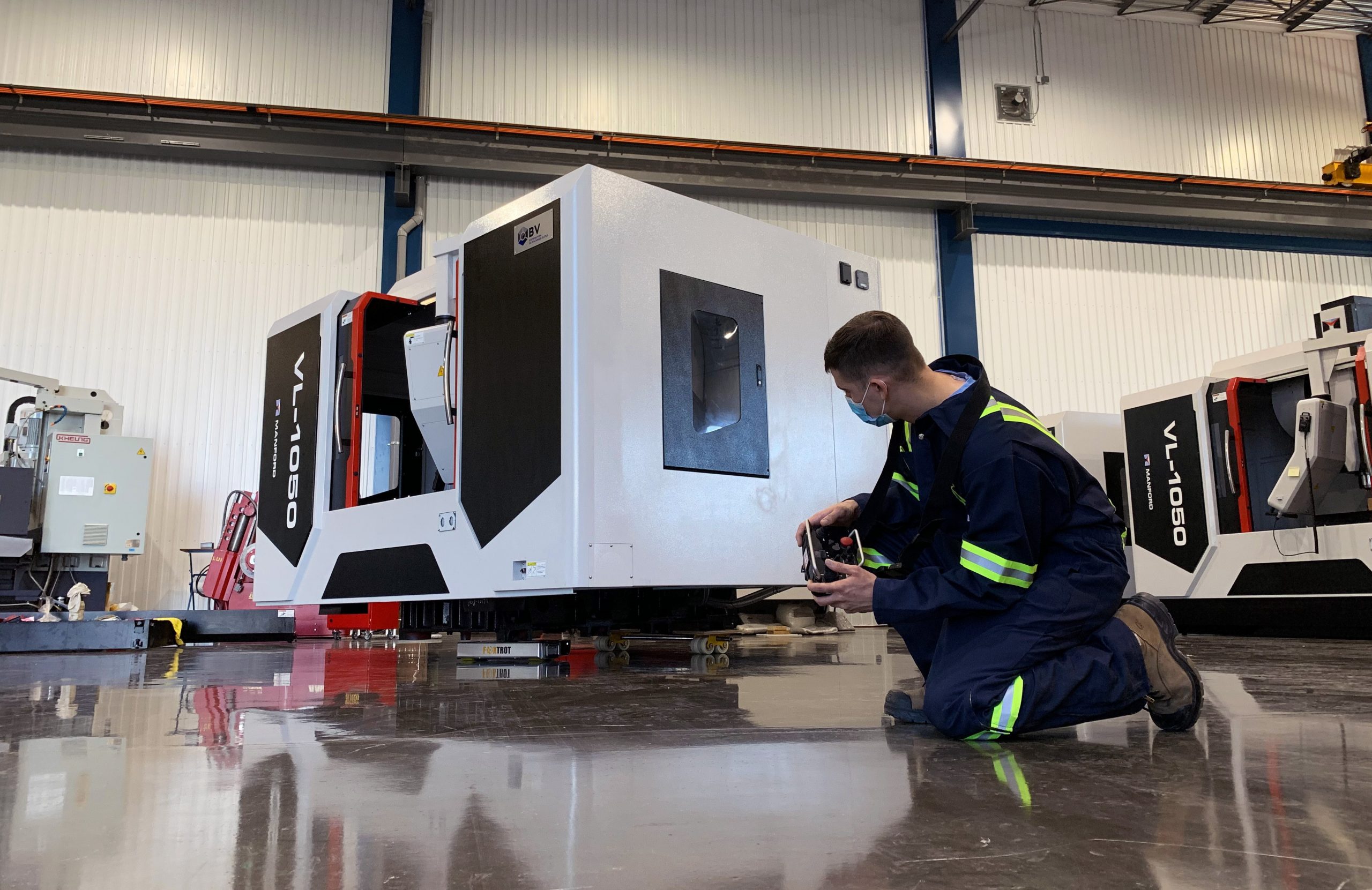

One of the main benefits of remote-controlled robots is to improve worker safety. By eliminating or reducing the need for employees to perform dangerous or physically demanding tasks, these robots significantly reduce the risk of injury and accidents. Operators can control the robots remotely, keeping them out of hazardous environments, such as high-temperature areas, confined spaces or sites with chemical hazards. Remotely controlled robots also make it possible to intervene in potentially dangerous situations, such as handling toxic or unstable materials, without directly exposing workers to the associated risks.

Versatility and adaptation to harsh environments

Remote-controlled robots are designed to adapt to a wide variety of industrial environments. Their versatility allows them to perform a variety of tasks, from heavy load handling to infrastructure inspection, maintenance and repair. These robots can be equipped with advanced sensors, high-resolution cameras and other cutting-edge technologies, allowing them to navigate complex environments and collect valuable data in real time. Whether working in cramped, hard-to-reach or high-risk areas, remotely operated robots offer a reliable and adaptable solution.

Reduce downtime and increase efficiency

By using remotely operated robots, companies can significantly reduce downtime and increase operational efficiency. These robots can work continuously, without fatigue or distraction, speeding up production processes, reducing lead times and optimizing resource utilization. In addition, because of their ability to operate in hazardous or hostile environments for humans, remotely controlled robots can perform maintenance and repair tasks faster and more efficiently, minimizing production interruptions.

Improved overall productivity

Remotely controlled robots have a significant impact on overall business productivity. By freeing workers from physically demanding or dangerous tasks, remotely controlled robots allow employees to focus on higher value-added tasks. This leads to an increase in overall company productivity. In addition, the precision and speed of remote-controlled robots reduce human error and delays, resulting in higher quality finished products and increased customer satisfaction.

Remotely controlled robots offer a multitude of benefits in the industrial setting, from improving worker safety to increasing operational efficiency and overall productivity. Their ability to perform tasks in challenging environments, reduce downtime and human error, and generate significant cost savings make them invaluable tools for businesses. By adopting remote robots, companies can not only improve profitability, but also create a safer and more productive work environment. As industry continues to move toward automation and robotization, remotely controlled robots will play an increasingly crucial role in improving business performance and competitiveness.

Recent Comments